정보공개

Smart Stable

-

- Share

- URL

/WEB-INF/jsp/k2web/com/cop/site/layout.jsp

english_JW_MS_K2WT002_S

english_JW_MS_K2WT002_S

Smart Stable

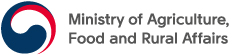

Concept of Smart Stable

- Farms with reduced labor and improved productivity by remotely and automatically controlling farm environment and livestock by converging information communication technology (ICT*) to livestock facilities

* Communication, sensors, security cameras, internet of things (IoT), big data, robots, artificial intelligence (AI), etc.

* Introduction Effect: Feed cost 9.2%↓, labor cost 6.6%↓, fertility rate 2.5%↑, improvement of grade 6.9%↑, damage cost from diseases 43.9%↓ (2016, Seoul National University)

Subjects of ICT Convergence Expansion Project in Livestock Sector

- Production & Business Management Program

- A farm business management program for controlling data related with breeding, diseases, feeding and management - Environmental monitoring and controlling device inside and outside livestock facility

- Environment controller, ventilator, air-conditioner and heater, fan, cooling pad, mist spray, hot air blower, (LED) illumination controller, integrated software, etc.

- Odor measuring system, odor reduction system, odor monitoring system, etc.

* The above listed devices must allow monitoring and controlling of farm environmental data on computer or mobile devices - Security Camera

- Limited to cameras capable of real-time remote controlling and monitoring anytime, anywhere

* Except analog security cameras that can only observe inside livestock facilities and cannot be linked to other devices - Automatic Equipment Capable of Remote (or Automatic) Control

- (Piggery) Automatic feeding system, computer liquid feeding system, drinking water controller, housing feeding system, feed efficiency measuring machine, feed bin controller, slaughtered pig sorter, estrous/pregnancy detector, weighing machine, etc.

- (Chicken & Duck Farm) Automatic feeding system, automatic watering system, egg sorter, incubator, drinking water controller, feed bin controller, weighing machine, etc.

- (Dairy & Korean Cattle Farm) Milking machine, robot milking machine, automatic feeding system, feed bin controller, drinking water controller, estrous detector, TMR mixer, TMR automatic feeding system, birth notification system, automatic calf feeder, bulky feed organizer, weighing machine, raw milk cooler, MCS gauge, etc.

* The above listed devices must allow monitoring and controlling of farm environmental data on computer or mobile devices

Project Application

- (Application Period) Constantly throughout year

- (Application Process) Recruitment of candidates from city/gun/autonomous district → consulting → selection of subject

- (Conditions) Net required amount up to KRW 1.5 billion (30% state, 50% loan, 20% deductible)

* Loan Interest Rate: 2% (3-year loan, 7-year repayment by installment) - (Information) Smart Farm Korea (www.smartfarmkorea.net)

- (Future Plans) To distribute smart livestock facilities to 5,750 farms or 22% of full-time farms that grow major livestock breeds (pig, chicken, Korean cattle or dairy) in the livestock industry by 2022

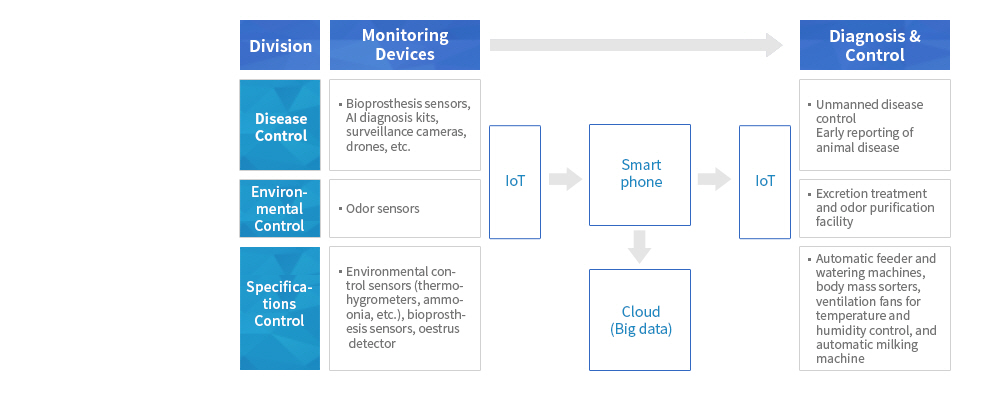

Schematic Diagram of Smart Livestock Facility

| Components | Details | |

|---|---|---|

| Pig Pen Management | Internal Environment Management Devices | Detect temperature, humidity, CO2 level, illumination, ammonia, carbon dioxide, and short circuit (blackout), etc. |

| External Environment Management Devices | Temperature, humidity, wind direction, rainfall, sunlight, wind speed, etc. | |

| Controllers | Gestation Pen | Estrus checker, sow feeder, feed bin, watering controller, etc. |

| Maternity Pen | Insulation lighting, sow feeder, feed bin, watering controller, etc. | |

| Piglet Pen | Insulation lighting, feed mixer, feed bin, watering controller, etc. | |

| Fattening Pen | Pig sorter, feed mixer, feed bin, watering controller, etc. | |

| Imaging Devices | Surveillance camera (web-camera), DVR, etc. | |

| Production Management System | Computer, monitor, etc. | |